Sustainable Aviation Fuel Needs Accelerating Sustainable Agriculture

By Mike Sticklen, LEC Partners

Sustainable Aviation Fuel needs Sustainable Agriculture.

Throughout my work with LEC Partners, I often get asked about producing renewable and biobased fuels, chemicals, and plastics from alternative feedstock sources such as cellulosic biomass or other waste. Many potential investors and policymakers believe alternative feedstocks will sustainably reduce greenhouse gas emissions while not competing with food crops such as corn.

There is growing demand from airlines for sustainable aviation fuel (“SAF”) produced with low carbon intensity and affordable production cost(s). The airline industry needs large-scale production within the next 5-10 years. Tony Cartolano’s recently published article covers the SAF opportunity quite well. Corn-based ethanol to jet fuel (ATJ) is one of the routes that can be scaled quickly while keeping production costs down. Corn-based ethanol is moving quickly to reduce its carbon intensity within the next 5-years while having low production costs at the scale the airline industry requires to supply 3 billion gallons of SAF by 2030 (aka “The Grand Challenge”). The question is: How can corn-based ethanol meet this challenge sustainably and with low carbon emissions?

SAF Needs Low Carbon Ethanol

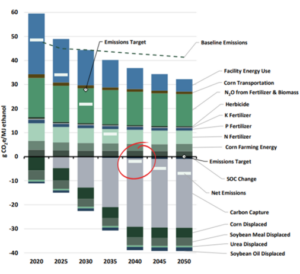

Figure 1 below illustrates the US ethanol industry’s commitment to reducing average fuel ethanol carbon intensity from 2020 to 2050. Corn-ethanol’s current average carbon intensity is 50 gCO2e/MJ ethanol which is one-half of gasoline carbon intensity of 100 gCO2e/MJ gasoline. The ethanol industry has committed to net-zero carbon intensity by 2040 and a 50% reduction to 25 gCO2e/MJ ethanol by 2030. Ethanol plants will achieve this reduction primarily through geological sequestration of fermentation CO2 (CCS) and continuous reduction in natural gas and electric power usage. This is underway currently with CO2 pipelines deep connecting to underground CO2 storage in North Dakota and Illinois and is being incentivized by the IRA 45Q CCS tax credit of $85 per ton CO2 and low-carbon fuel standard carbon credits. The pipelines have some political headwinds, but I think they will be built slower than planned. The benefits to farmers, ethanol producers, and society are too large to ignore. Ethanol producers continue reducing their GHG footprint with technologies such as membrane dehydration, advanced process control, behind-the-meter renewable power, and ethanol and distillers’ corn oil yield improvements. Inside the fence, ethanol plant GHG emissions will be reduced from 26 gCO2e/MJ to 16 gCO2e/MJ by 2030.

Figure 1. Corn-based fuel ethanol carbon intensity forecast

(RFA Study Pathways to Net Zero – Emery Informed Sustainability Consulting)

Low Carbon Ethanol needs Sustainable, Low Carbon Corn

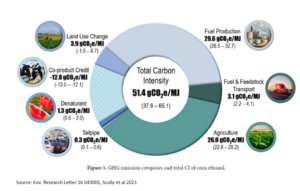

Corn feedstock currently accounts for 26 gCO2e/MJ ethanol or 51% of total net ethanol GHG emissions (Figure 2), with ethanol production contributing most of the GHG balance.

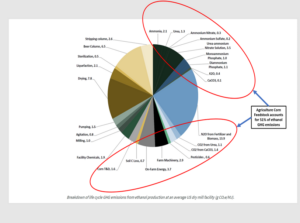

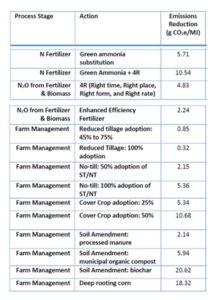

The opportunities to reduce corn ethanol feedstock GHG emissions are illustrated in Figure 3 and Table 1. Figure 3 shows the total life-cycle greenhouse gas emissions breakdown for an average US corn ethanol plant. The pie slices that are circled in red are the GHG emissions from farming, harvesting and transporting corn to the ethanol plant. The top GHG contributors are nitrous oxide emissions from nitrogen fertilizers and biomass degradation, fertilizer manufacturing carbon intensity, and farming fuel use, including drying. Table 1 shows the estimated ethanol GHG reduction achieved by various improvements to farming and conversion to renewable fertilizer. The top opportunities (1 through 6) are listed below:

Figure 2. Corn Ethanol Agriculture GHG Intensity is 51% of net emissions (Argonne GREET)

- Continuing to improve crop yields. More bushels on less land reduce indirect land use, improve farming energy efficiency, and reduce fertilizer intensity.

- Applying the right fertilizer in the right place, at the right application rate, and at the right time (4R’s). Smart-farming practices can enable 4R’s, reducing farming input cost and nitrous oxide (N2O) emissions by up to 50%. N2O GHG effect is 300 times worse than CO2.

- Adopting no-till or strip-till practices. Requires farmers to change long-established practices while maintaining carbon in the soil and reducing N2O emissions.

- Adopting cover crops that fix nitrogen grown in addition to corn and soybean cash crops, resulting in less nitrogen fertilizer use and reduced N2O emissions. This option is not without risk to farmers – with potential adverse effects on other crop yields.

- Using renewable “blue or green” nitrogen fertilizer. Blue ammonia is more likely to be widely available via Louisiana ammonia producers geologically sequestering CO2 that is produced with traditional ammonia production. This will reduce the GHG intensity of ammonia transported via pipeline to the midwest corn belt. Green ammonia produced via renewable hydrogen from wind and solar power is being helped by the IRA hydrogen production tax credits.

- Applying biochar to soil. This has the potential to bank CO2 emissions in soil and reduce GHG intensity by 20 gCO2e/MJ, but the biochar supply chain is not established, and application to fields is not yet well understood. This magnitude is exciting, however, it is several years out.

Figure 3. Top Agriculture GHG Contributors are N2O, Fertilizers, and Farming Fuel Use

(RFA Study Pathways to Net Zero – Emery Informed Sustainability Consulting)

Table 1. Corn Ethanol Potential CI Reduction Opportunities

4R’s, cover crops, renewable ammonia, and reduced soil tillage can reduce ethanol GHG emissions by 20 gCO2e/MJ

(RFA Study Pathways to Net Zero – Emery Informed Sustainability Consulting)

Sustainably Grown Corn has the Scale Required to Remove sufficient atmospheric carbon to slow down climate change.

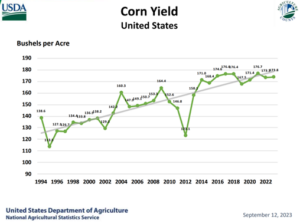

The technology that drives sustainable production of corn continues to advance at an increasing pace. Today’s crops provide a low-cost and climate-friendly feedstock for producing sustainable starch and oil feedstocks for producing renewable fuels, chemicals, and plastics. US corn farmers are growing more corn on less land as measured by average yield (Figure 4). Efficient row crop growth captures vast amounts of CO2 via photosynthesis using solar energy. When the carbon that is captured in the plants is converted to carbohydrates, oils, and proteins, the carbon adds value to society via food, fuel, and other materials. The biogenic carbon released during some manufacturing processes, such as fermentation, can be captured and stored. A few novel non-fermentation manufacturing processes utilize almost all the carbon. No other carbon cycles can achieve the scale needed to combat GHG build-up in our atmosphere.

Average corn yield has improved from 137 bushels per acre to 174 bushels per acre since 2000, a 27% improvement (Figure 5). Accelerating U.S. yield improvements of corn and soybeans will continue to supply increasing quantities of starch and oil per acre of land. Land-use efficiency continues to accelerate with reduced cycle time for crop trait improvements. One example is the development of corn plants with shorter stalks, which make them less prone to wind damage, reducing yield loss and improving overall yields. Deeper root corn is another crop innovation that could reduce GHG intensity by almost 20 gCO2/MJ by enabling the corn plant to sequester more carbon in the soil via the roots; this will take much longer to be developed (Paustian, K., Larson, E., Kent, J., Marx, E., & Swan, A. (2019). Soil C sequestration as a biological negative emission strategy. Frontiers in Climate, 1, 8.)

Precision agriculture using satellite-guided planting, fertilizer application, and real-time crop yields will result in a step-change reduction in corn inputs, especially nitrogen fertilizer. Nitrogen fertilizer application to corn is the largest contributor to greenhouse gas emissions for corn ethanol and the agricultural industry from nitrous oxides (N2O). Famers are fast adopting no-till or strip-till farming practices, reducing crop carbon intensity and improving yield. Some farmers are starting to grow non-food cover crops such as alfalfa, pennycress, and clover as an additional means to add nitrogen to soil instead of fossil fuel ammonia. This requires a steep learning curve and risk-taking by leading farmers with the risk of adversely impacting their primary cash crop. Farmers will need a financial incentive through crop GHG reduction monetization to help accelerate some of the more risky changes.

Figure 4. US Average Corn Yield Trend

Corn Ethanol plants supply both food and fuel.

The world’s supply of carbohydrates will exceed the demand for food for years to come. While proteins and oils are tight, starches from corn, wheat, rice, and other tropical crops are plentiful.

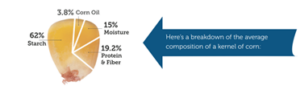

Corn is a starch “machine” containing over 62% starch commercially (Figure 6). Corn also contains protein and oil. The corn protein is a valuable feedstock for aquaculture and poultry, the fastest-growing animal protein. Distillers’ Corn Oil is a low-carbon feedstock for Renewable Diesel and SAF. Corn ethanol can supply both food and fuel.

Figure 6. Corn kernel composition

Cost Effective Cellulosic Biofuels will require a technology breakthrough.

The total cost for cellulosic ethanol, including capital charge, is 50% higher than corn ethanol. Major technology breakthroughs are required to level the playing field. Several premier technology companies have tried the cellulosic feedstock route, including DuPont, POET, Abengoa (Italian producer), and Clariant Romania. Their unit capital costs were around $10 per gallon compared to current corn ethanol at $3 per gallon. Cellulosic ethanol has a feedstock cost advantage over corn, with corn stover priced at $80 per ton, however, corn ethanol has superior co-product credits for distillers’ corn oil, distillers’ grains, and protein feed. Corn ethanol has a lower unit fixed cost due to scale, with cellulosic ethanol having higher enzyme and chemical costs. The cellulosic fuel plants have small capacities of around 25 million gallons per year compared to corn ethanol plants from 60 to 250 million gallons per year. There are over 190 operating ethanol plants in the US, and no cellulosic ethanol plants. Newcomers such as Verbio and D3MAX are continuing to innovate: Verbio is converting corn stover to Renewable Natural Gas (RNG) via digestion, and D3MAX has adapted NREL mild cellulosic hydrolysis technology at Ace Ethanol. In terms of total fuel energy output, these plants are also small.

Conclusions

Sustainable farming practices and fertilizer GHG intensity reduction alternatives will be major contributors that enable corn ethanol to become a top feedstock for the new sustainable aviation fuel industry. Farming practices, including 4Rs, renewable fertilizers, and reduced soil tillage, will reduce corn GHG intensity in the next five years. Biochar soil amendments and cover-crop adoption will increase negative ethanol GHG intensity by 2040.

About the Author. Mike Sticklen has over 40 years of experience in biological and chemical process industries, including Innovation Director, VP of Engineering and Technology, VP of Operations, and Plant Manager at companies such as Flint Hills Resources, Hawkeye Renewables, Dow Chemical, and DuPont. He currently serves as LEC Partners as a Project Director for projects ranging from $200MM to $3+ billion, overseeing matters involving Ethanol Protein/CI, Bioplastics, Mfg. Best Practices, Green Hydrogen, Hydrogen Derivatives.

Have some questions?

Not sure where to start?

Let's start a conversation. We're here to help you navigate

the bioeconomy with confidence.