Enzyme Use in Textiles

Enzymes are complex protein molecules produced by living organisms. Their function is to make chemical reactions proceed rapidly to continue life. In nature, they are responsible for digesting food and composting trees. Humans have learned to adapt the activity of enzymes for their use in manufacturing valuable materials. Typical commercial applications of enzymes range from cheese-making to laundry detergents. Many industries use enzymes, including pharmaceutical manufacturing, leather processing, textiles, paper-making, and biofuels.

In the past twenty years, the enzymatic process has proven to be a beneficial financial and ecological alternative to harsh chemical processes. This is because biodegradable enzymes work at ambient temperatures and in water-based solutions. Although many industries have adopted them, opportunities continue to increase in many business sectors to replace harsh chemicals.

Enzymes are categorized according to the compounds they act upon. Some of the most common ones include:

- Proteases, which break down proteins into amino acids

- Amylases, which break down starch into simple sugars

- Cellulases, which break down cellulose into glucose

- Lipases, which split fats (lipids) into glycerol and fatty acids

- Oxidation/reduction enzymes, which move electrons

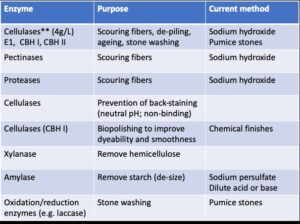

Let’s look at examples of enzymes used in the textile industry.

What are these processes for enzyme use in textiles?

De-sizing: When cotton threads are woven into cloth, the warp threads (longitudinal stationary) threads are coated with starch to ease weaving. Once the cloth is made, the starch must be removed for subsequent fabric treatments. Scouring is done to the cotton fabric to remove non-cellulosic components from native cotton, such as wax, hemicelluloses, and mineral salts, to even wettability. Stonewashing is done to “age” denim and other fabrics for consumer choice. This can be accomplished with pumice stones, but neutral cellulase or laccase is easier on the fabric. Bleaching removes some of the dye on the material to create special effects.

The bleach must be cleaned up to prevent continued contact with and potential damage to the fabric. Biopolishing reduces fiber fuzz and piling on the fabric surface.

Advantages of enzyme applications in textile processing:

- Extremely specific nature of enzyme reaction, with practically no side effect.

- Low energy requirements, mild conditions of use, safe to handle, non-corrosive in their applications.

- Large quantities of chemicals can be replaced in textile processing with enzymes.

- Ease of biodegradability of enzymes results in reduced loads on the environment.

- Enzymes, under unfavorable conditions of pH or temperature, remain chemically in the same form, but their physical configuration may be altered, i.e., they are “denatured” and lose their activity. For this reason, steam must never be injected into a bath containing enzymes and must be done in pre-diluted form.

- Enzyme compatibility with ionic surfactants is limited and must be checked before use.

- Enzymes have high sensitivity to pH, heavy metal contamination, and temperature range.

- Enzymes applied to textiles have lower discharge of chemicals and wastewater.

- Enzymes improve fabric quality because of less harsh conditions for treatment.

- Enzymes allow more extended garment life/wear due to lower damage to the original fabric.

- Enzymes allow a reduced chemical load, water consumption, and energy consumption.

Partner with LEC for Enzyme Success

At LEC Partners, we are dedicated to helping businesses of all sizes achieve sustainable and successful outcomes. Whether you’re a startup or a multinational company, our community of world-renowned bioeconomy experts has the experience and expertise to guide you to success.

Why Choose LEC Partners?

- Unmatched Bioeconomy Expertise: As trusted leaders in the bioeconomy, we deliver sustainable and profitable results, guiding projects from planning to execution.

- Customized Teams: Your project is unique, and so is our approach. We assemble a custom team to meet your specific needs, whether you require one expert or many.

- Streamlined Communication: No matter the size of your project team, you will always have a single point of contact for seamless coordination and communication.

- Comprehensive Services: Beyond engineering, operational, and financial guidance, we offer additional services like regulatory support and expert witness testimony, to ensure you are covered from every angle.

Ready to Transform Your Enzyme Business?

Take the next step and partner with us to shape the future of your Enzyme business. Contact us today to learn how our community of over 180 bioeconomy experts can help you achieve your goals.

References:

M. Hossen Uzzal; B.Sc. in Textile Technology; Monno Fabrics Ltd. Manikgonj

Winkler, Florian; 2014; Enzymes—an eco-friendly alternative for the textile industry? StepChange blog.

See also: Catalysts & Enzymes in Biofuels Fuels Production; Enzyme Experts; Enzyme Technologies.

Have some questions?

Not sure where to start?

Let's start a conversation. We're here to help you navigate

the bioeconomy with confidence.