Unlocking the Future of Plastic Waste: Pyrolysis Oil’s Role in Sustainable Innovation

Plastic waste is a growing global challenge. Thankfully, advanced recycling technologies are stepping in as a beacon of hope. Among the most promising innovations is pyrolysis oil, produced from post-use plastics. It offers a powerful solution to reduce environmental impact while addressing the plastic waste crisis head-on. Drawing from multiple projects and life cycle analyses (LCAs), let’s explore how pyrolysis oil sets new sustainability standards across the plastics and recycling industries.

You can also explore a recent case study on our in-depth assessment of a pyrolysis oil production facility, where LEC Partners evaluated the technology’s scalability, efficiency, and market potential for converting waste materials into renewable energy sources.

The Global Challenge: Plastic Waste and Greenhouse Gas Emissions

Plastic waste continues to be one of our most urgent environmental issues. Conventional waste management techniques—like landfilling and incineration—can’t keep up with the rising levels of plastic production. Worse, they contribute heavily to greenhouse gas (GHG) emissions, further exacerbating the climate crisis.

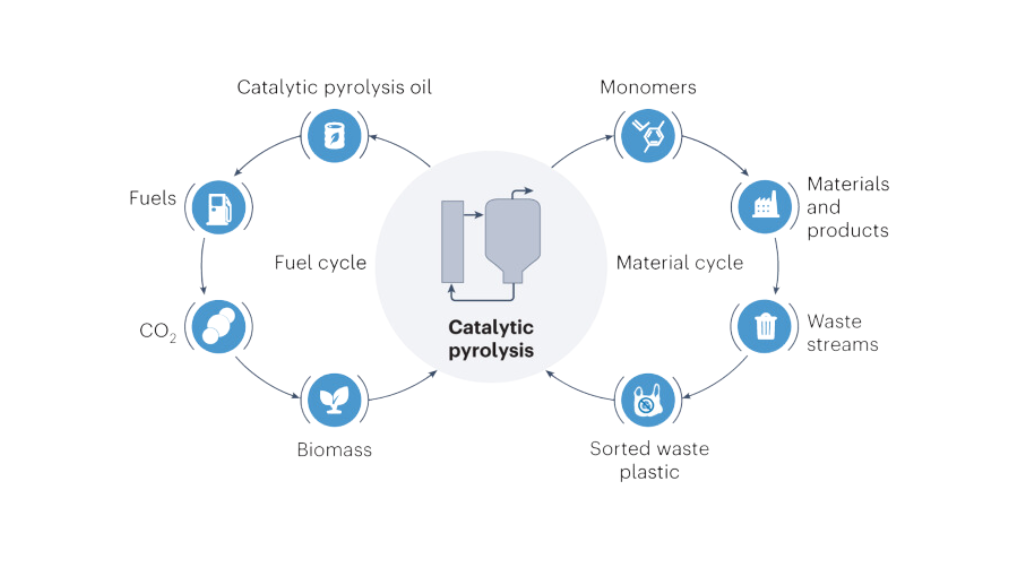

So, what’s the alternative? Pyrolysis. This advanced thermal process converts waste plastics into oil, giving us a new opportunity to tackle both the waste and carbon emissions problems. But how does pyrolysis oil compare to traditional fossil-fuel-based plastic production? That’s where LCAs provide the critical insights we need.

Key Findings: Environmental Benefits from Multiple Pyrolysis Projects

Recent LCAs from several U.S.-based recycling projects show how much environmental potential pyrolysis oil holds. These projects process various waste plastics—like HDPE, LDPE, PP, and PS—into a drop-in feedstock for producing recycled plastics. Each LCA demonstrated a significant reduction in GHG emissions when using pyrolysis oil compared to conventional fossil-based feedstocks, such as naphtha.

Across these projects, we saw GHG reductions ranging from 75% to 115%. These results are impressive even after accounting for the energy inputs required by the pyrolysis process. It’s clear: pyrolysis oil is a cleaner, more sustainable alternative to fossil-based plastic production.

Pyrolysis Oil vs. Fossil Fuels: A Comparative Analysis

LCAs compared the emissions from producing pyrolysis oil with conventional naphtha production, a common fossil-based feedstock in plastic manufacturing. Pyrolysis oil production is a multi-step process: it starts with the collection and sorting of post-use plastics, followed by thermal treatment in a pyrolysis reactor, where the plastics are broken down into oils, gases, and char. The resulting oil can be refined and used in place of naphtha in plastic production.

While both processes aim to produce plastics feedstock, the environmental edge goes to pyrolysis oil. The LCAs showed that even with the energy demands inherent in the pyrolysis process, its overall carbon intensity is significantly lower than that of naphtha. Add in the avoided emissions from waste plastics that would otherwise be incinerated or landfilled, and the benefits of pyrolysis oil become even more pronounced.

Scaling Sustainability: A Solution for the Future

One of the most encouraging themes from these projects is scalability. The analyzed facilities are built to handle large volumes of post-use plastics, proving that pyrolysis oil production is not only feasible but also scalable. As industries and policymakers shift toward circular economy models, where waste is treated as a resource, technologies like pyrolysis will be essential in bridging the gap between sustainability and profitability.

These analyses also point out opportunities for ongoing improvement. While the environmental benefits of pyrolysis oil are undeniable, we can’t stop here. Continuous innovations in process efficiency and energy use will be crucial in maximizing the potential of pyrolysis oil. With a focus on cost-effectiveness and operational scalability, this technology can become a cornerstone in sustainable plastic production.

Conclusion: A Sustainable Path Forward for Plastics

The insights from multiple LCAs offer a hopeful vision for the future of plastic waste management. Pyrolysis oil doesn’t just reduce GHG emissions; it provides a sustainable solution to one of the world’s most pressing environmental challenges. These projects show that by adopting advanced recycling technologies like pyrolysis, industries can significantly lower their carbon footprints while turning waste into valuable resources.

As businesses, governments, and investors strive to build sustainable futures, pyrolysis oil stands out as a key innovation in the shift to a circular economy. This multi-project analysis highlights its potential to revolutionize the plastics industry, offering both environmental and economic benefits. With the right commitment to scaling and improvement, pyrolysis oil is on track to become a mainstream solution in sustainable plastic production.

Take the Next Step Toward Sustainability Are you ready to make a difference? Contact us today to explore how advanced recycling technologies like pyrolysis can help you achieve your sustainability goals while reducing your environmental impact. Let’s work together to create a cleaner, more circular future.

Have some questions?

Not sure where to start?

Let's start a conversation. We're here to help you navigate

the bioeconomy with confidence.