Production of Hydrogen at Industrial Scale

State of the Art and Future Prospects

Qi Chen, LEC Partners

Introduction

In the quest for a sustainable energy future, hydrogen has been recognized as a key, offering versatile applications across industries. It has become a vital vehicle of decarbonization. As we delve into the intricate landscape of industrial-scale hydrogen production, this paper aims to unravel its applications and consumptions, diverse production routes and technologies, current market dynamics, and future challenges and prospects. Considering the audience of the paper, the topics are addressed at a high level and largely qualitatively. Detailed information can be found in some references cited in the paper. Additionally, the author will be happy to respond to any comments and queries.

Hydrogen Applications and Consumptions

Hydrogen has been produced at the industrial scale for many decades in diverse applications, see Figure 1. Traditional applications are mainly in chemical manufacturing and oil refining, with some lower volumes in synthetic liquid hydrocarbon fuels in certain geographic regions. In the chemical industry, hydrogen serves as a fundamental feedstock, contributing to the synthesis of vital chemicals such as ammonia and methanol. In oil refineries, hydrogen plays a pivotal role in upgrading crude oil fractions, elevating the quality of refined products by increasing their hydrogen content with the so-called hydroprocessing technologies. Synthetic liquid hydrocarbon fuels are produced at industrial scale in South Africa, China, and the Middle East. The former two countries use coal as the feedstock for producing liquid fuel, while in the latter region natural gas feed is used. In both cases, fossil fuels are converted to a mixture of hydrogen and carbon monoxide called synthesis gas or “syngas.”

More recent applications are found in the metallurgic industry, where hydrogen has been used to reduce minerals to metal, e.g., iron in direct iron reduction or DIR process technology. This would reduce the carbon emission of the metals industry, which is considered a difficult-to-decarbonize sector. In the transportation and automotive landscape, the rise of hydrogen-powered fuel cells offers a cleaner alternative to conventional internal combustion engines. This is championed as an important route to decarbonize the mobility sector, at least in some regions like Japan and Korea. In yet another major application, hydrogen is used for heat and power generation to replace fossil fuels. Because this application uses hydrogen directly, the potential volume of consumption can be huge, if widely adopted.

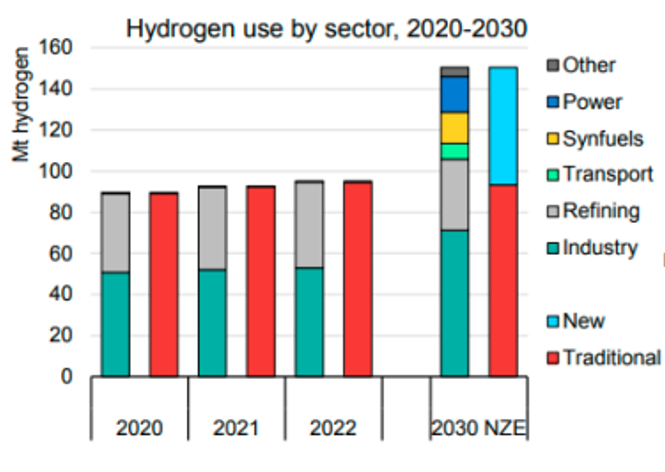

Global hydrogen consumption is just below 100 million tons in 2023, with the traditional application contributing the bulk. The annual growth in 2022 amounts to a modest 3 %. The forecast for future consumption shows that the new applications will increase significantly, while the traditional uses stay stable, see Figure 2. Although the momentum for hydrogen consumption is tremendous, a substantial volume increase in uptake in new applications is yet to be materialized.

Figure 1 Applications of hydrogen. Courtesy US EIA, Ref 1

Nevertheless, it is the consensus today that hydrogen has the potential to revolutionize energy consumption patterns during the current energy transition period. The adaptability of hydrogen therefore positions it as a key player in the global pursuit of a low-carbon economy.

Figure 2 Hydrogen consumption by sector, Ref 2

Production Routes and Technologies

Although hydrogen is the most abundant atom, hydrogen gas does not exist in nature. It must be generated from a source containing hydrogen atoms, usually water and/or hydrocarbons. Traditionally, two dominant routes have been followed for the production of hydrogen at an industrial scale, steam methane reforming (SMR) and partial oxidation (POX) of fossil fuels, gas, oil, and coal. Autothermal reforming is a combination of reforming and POX, which has become more popular recently because of its potential for pre-combustion CO2 capture in the process.

Electrolysis of water is a century-old and simple electrochemical process that uses electricity to split water into hydrogen and oxygen. It has become highly popular in recent years, following the global trend of reducing carbon emissions, because its production does not involve any fossil fuel. Large-scale electrolysis, powered by renewable energy sources such as solar and wind, and sometimes hydro and nuclear, is gaining prominence as a green alternative to conventional hydrogen production methods.

Recently, biomass and solid wastes such as MSW have been used as fuels to produce hydrogen. This is an interesting route. However, because of the limitations of the availability of the fuels, it can only contribute to global hydrogen production to a limited extent. Researchers produce small amounts of hydrogen by pyrolysis of CH4 with pure carbon as the by-product. At the moment, various other innovative routes are being experimented with.

The industry gives a color code to the hydrogen produced by these processes. Grey hydrogen is produced from fossil fuels with SMR and POX. When CO2 is captured from the facilities, the hydrogen thus produced is painted blue. When water electrolysis generates hydrogen with renewable power from, e.g., wind and solar, the hydrogen is then coined green. It is a little complicated and still in debate about what color should be given to the hydrogen produced from biomass and waste. Hydrogen from the pyrolysis of CH4 with a by-product carbon is colored turquoise, etc.

Steam Methane Reforming (SMR)

SMR is the most widely used method for industrial hydrogen production, accounting for the major portion of the global hydrogen supply. This process involves reacting methane (CH₄) with steam (H₂O) in the presence of a catalyst to produce hydrogen and carbon dioxide. SMR offers advantages such as high efficiency and the ability to handle large-scale production. The existing infrastructure is well-suited for SMR. Currently, it is the most cost-effective way to produce hydrogen.

One major challenge the SMR faces now is its carbon footprint. The production of hydrogen through SMR results in the release of carbon dioxide, although SMR emits the least CO2 among the conventional routes using fossil fuels. Major players in the sector have been actively exploring carbon capture and storage (CCS) technologies to mitigate these emissions. Implementing CCS in SMR facilities can capture and store CO₂, reducing the environmental impact of this widely used production route. Shell and Air Products are two pioneers who demonstrated the CCS feasibility for SMR facilities at a scale of one million tons of CO2 reduction per year. Ref 3.

Partial Oxidation (POX)

Partial Oxidation involves reacting fuels with oxygen to produce syngas. The term is interchangeably used with its other name Gasification. This process is often used with coal and heavy hydrocarbons as feedstock, such as residue oil. POX presents a well-established, efficient method for generating hydrogen-rich gas streams at an industrial scale. POX offers an advantage over SMR in industries where hydrogen and carbon monoxide are required simultaneously, such as in Fischer-Tropsch synthesis for liquid fuels.

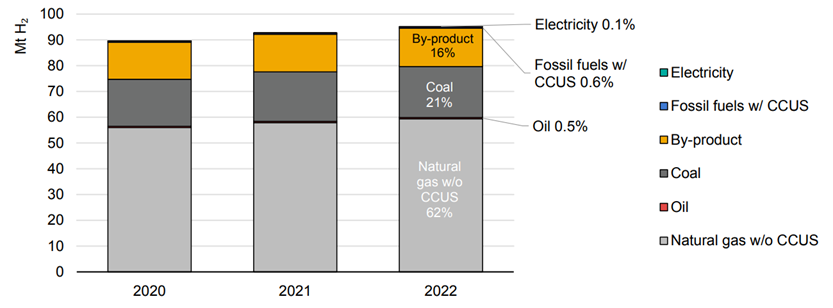

Coal gasification has had a particularly welcoming adaptation in China. With the incorporation of hundreds of huge facilities over the past two decades, the global landscape of hydrogen production has been influenced, such that gasification became a significant route of hydrogen production, taking over market share from SMR, see Figure 3. This formed the basis of a coal-based chemical industry, which is unique in the world. The author of this paper has participated in and contributed to the rapid development of China’s coal gasification industry.

Autothermal Reforming

Autothermal Reforming combines features of both SMR and POX, involving the reaction of hydrocarbons with oxygen and steam, producing hydrogen, carbon monoxide, and carbon dioxide. Autothermal Reforming is celebrated for its efficiency gains compared to traditional SMR and POX, integrating the exothermic and endothermic reactions within a single process. This makes it an attractive option for industries seeking to optimize both energy consumption and hydrogen production.

Carbon capture and storage (CCS) has been incorporated into hydrogen production facilities to cut carbon emissions. For this purpose, auto thermal reforming and POX are advantageous compared to SMR, because CO2 is generated within the process gas and is easier to remove. This is the so-called pre-combustion capture, while at least a part of the CO2 must be captured from flue gas in an SMR plant via the post-combustion capture. That is why new blue hydrogen plants favor autothermal reforming technologies.

Electrolysis

Electrolysis, particularly when powered by renewable energy sources, is gaining momentum as a green alternative. This process involves splitting water into hydrogen and oxygen using electricity. The global installed electrolysis capacity may have reached 2 gigawatts by the end of 2023, equivalent to 300,000 tons of hydrogen. This showcases the growing significance of electrolysis in large-scale hydrogen production.

Electrolysis offers a direct path to green hydrogen production if it uses electricity generated from renewable sources. As the share of renewable energy in the global energy mix increases, the environmental footprint of electrolytic hydrogen production decreases.

Market Dynamics

Electrolysis, especially when powered by renewable energy sources, is becoming a viable option. This process involves splitting water into hydrogen and oxygen using electricity. The global installed electrolysis capacity may have reached 2 gigawatts by the end of 2023, equivalent to 300,000 tons of hydrogen. This showcases the growing significance of electrolysis in large-scale hydrogen production. Electrolysis offers a direct path to green hydrogen production if it uses electricity generated from renewable sources. As the share of renewable energy in the global energy mix increases, the environmental footprint of electrolytic hydrogen production decreases.

Figure 3. Hydrogen production – share of each technology, Ref 5

Challenges and Future Prospects

The cost of large-scale hydrogen production remains a significant challenge, particularly for green hydrogen produced by electrolysis. In 2020, the cost of hydrogen from renewable electrolysis ranged from $3 to $6 per kilogram. As a reference, SMR gray hydrogen can be produced at a $2/kg levelized cost. Green hydrogen is expected to undergo a substantial cost reduction. Projections indicate a potential 50% reduction in the cost of green hydrogen by 2030, further propelling its competitiveness in the global energy landscape. Economies of scale, speedy deployment, technological advancements, and supportive policies are essential to reduce production costs and increase competitiveness.

Infrastructure development is another critical challenge. The existing infrastructure along the hydrogen value chain for feedstock, production, storage, and transportation is predominantly designed for conventional methods, necessitating substantial investments to accommodate the evolving landscape of green hydrogen growth. The integration into existing industrial processes and the development of a comprehensive hydrogen infrastructure along the complete value chain are crucial strategies.

The utilization of hydrogen in conventional industrial processes, such as metal and cement industries, is a key factor in shaping the future landscape of large-scale hydrogen production.

Although green hydrogen by electrolysis will grow exponentially, blue hydrogen production by SMR or POX combined with carbon capture and storage will stay competitive and be applied to a large extent. Continued innovations in materials and catalysts will improve efficiency further. Advanced catalysts can enhance reaction rates, increase selectivity, and reduce energy requirements. The projection is that the blue hydrogen will still share one-third of the lower-emission hydrogen, with the rest coming from electrolysis by 2030.

Conclusions

Industrial large-scale hydrogen production is a key enabler of the global transition towards a low-carbon and sustainable energy future. It represents a multifaceted challenge and opportunity. Addressing challenges related to cost, infrastructure, industrial adaptation, and technology advancements is essential to unlock the full potential of hydrogen as a clean energy carrier. The ongoing evolution of production feedstocks and technologies, coupled with strategic investments and supportive policies, will play a decisive role in shaping the trajectory in future years. As hydrogen solidifies its role in the global push toward a sustainable and low-carbon future, continued R&D, speedy deployment, and investments will be paramount. Collaboration between governments, industries, and research institutions is essential for overcoming challenges and realizing the vision of hydrogen as a cornerstone of the future energy landscape.

About the Author

Qi has a Ph.D. in Chemical Engineering from the University Ghent in Belgium, and over 30 years of experience leading technology, development and execution teams. Based in The Netherlands, Qi specializes in process technologies and project engineering for the manufacturing of syngas and hydrogen, liquid fuels, and petrochemicals, with an emphasis on minimizing carbon footprints. He focuses on research and development, demonstration, deployment, and commercialization of process technologies of thermochemical conversions at temperatures of 800-1600 ̊C, such as gasification, pyrolysis, and steam reforming. With feedstocks, Qi continues to work with renewable resources like municipal solid waste (MSW) and non-recyclable waste plastics. At LEC, Qi serves as an expert in matters involving syngas, hydrogen, gasification, pyrolysis, solid waste feedstocks, natural gas, oil refining, and chemicals.

About LEC Partners

LEC Partners has over 180 experts that can help navigate your bioeconomy needs. If you need assistance with your bioenergy project(s), please Contact Us.

References

Ref 1: Applications of hydrogen. https://www.eia.gov/energyexplained/hydrogen/production-of-hydrogen.php

Ref 2: Hydrogen consumption by sector. https://www.greentechlead.com/renewable-energy/global-hydrogen-landscape-revealed-in-ieas-2023-global-hydrogen-review-44026

Ref 3: IEA report on Shell and AP CCS projects. https://ieaghg.org/exco_docs/2017-02.pdf

Ref 4: Green hydrogen capacity 2023. https://joint-research-centre.ec.europa.eu/jrc-news-and-updates/water-electrolysis-and-hydrogen-growing-deployment-prospects-europe-and-beyond-2023-11-24_en#:~:text=Beyond%20Europe%2C%20estimations%20of%20global,are%20growing%20year%20after%20year.

Ref 5: Hydrogen production capacity by technology. https://iea.blob.core.windows.net/assets/ecdfc3bb-d212-4a4c-9ff7-6ce5b1e19cef/GlobalHydrogenReview2023.pdf

Have some questions?

Not sure where to start?

Let's start a conversation. We're here to help you navigate

the bioeconomy with confidence.