Improving Anaerobic Digester Performance: What Happens When Mixing Fails

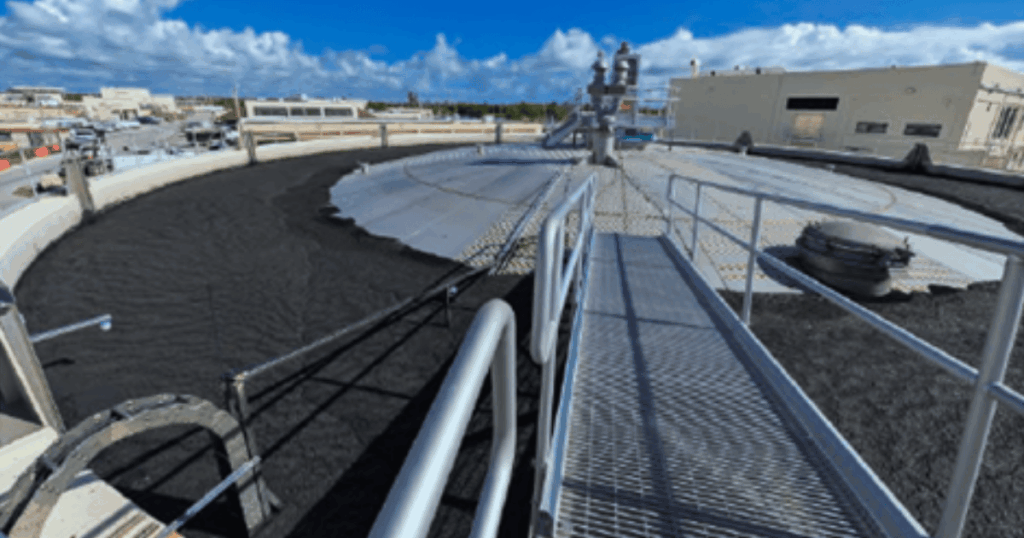

When it comes to anaerobic digesters, sound mixing isn’t optional — it’s the heartbeat of the process. It drives biogas production, keeps solids in suspension, and maintains a stable biological environment.

But as one major municipal utility learned, even a well-planned upgrade can deliver disappointing results if flow behavior isn’t fully understood.

When a Mixing Upgrade Backfires

After installing new linear-motion mixers and gas-holder covers, the utility expected higher efficiency and reduced maintenance. Instead, gas production fell by nearly half, digesters began to foam, and one stainless-steel cover started to deform under pressure.

It quickly became clear that the issue wasn’t biological — it was mechanical and hydraulic in nature. The system wasn’t mixing the sludge effectively.

The Root Cause: Flow and Rheology

Field observations showed that the new mixers produced movement only near the impeller, leaving large portions of the sludge volume stagnant. A CFD image from the equipment vendor’s literature further illustrated the concern: localized velocity near the mixer and little movement toward the tank walls.

Illustrative representation of Computational Fluid Dynamics (CFD) showing velocity distribution inside an anaerobic digester. This diagram is conceptual and not derived from project data.

The sludge’s non-Newtonian rheology — its resistance to shear and flow — likely played a role. Anaerobic sludge thickens as flow slows. When mixing energy is insufficient, dead zones form and gas can become trapped.

The gas-holder covers further impacted performance. Built with 4-foot skirts (half the standard 8-foot depth) and shorter guide columns, they flexed under pressure, creating uneven mechanical stresses.

LEC Partners’ Investigation

The utility brought in LEC Partners to perform an independent engineering assessment. The team — John Forcier, P.E., Greg Benz, P.E., and Terry Mazanec, Ph.D. — conducted field inspections and reviewed operating conditions to identify the source of performance loss.

The Investigation Included (Completed Work):

- Structural Review (Completed) – Assessment of gas-holder skirt height, guide length, cover stability, and mechanical stress behavior.

Recommended as Part of a Phased Recovery Plan:

- Sludge Rheology Testing (Planned) – Sludge samples will be sent to the University of Florida for laboratory analysis of viscosity and yield stress.

- CFD Flow Modeling (Planned) – Once rheology data is available, CFD and Kaemix modeling will be performed to visualize internal flow and identify dead zones.

- Pilot Testing (Planned) – Wet testing using actual sludge, followed by a full-scale trial with a different mixing technology.

Project Completion Date: October 2025

Key Insights

- Mixing performance must reflect actual sludge rheology, not water-like assumptions.

- CFD modeling can identify flow problems once rheological data is available and before costly retrofits are required.

- Cover geometry directly affects digester pressure stability and mechanical reliability.

- A phased rehabilitation approach allows incremental improvement with lower capital risk.

Results and Outlook

Full testing, rheological analysis, and CFD modeling have not yet been completed, and therefore no performance results have been realized to date.

However, preliminary engineering analysis suggests the potential for improvements once corrective actions are implemented, including:

- Restoring design throughput of ~100,000 gallons per day per digester

- Increasing biogas yield

- Reducing sludge hauling and disposal volume through improved solids destruction

- Improving cover stability with revised skirt and guide geometry

- Enhancing renewable energy contribution toward meeting plant power demands

Frequently Asked Questions

Why did performance drop after the upgrade?

The linear-motion mixers didn’t provide full-tank mixing. Stratified sludge and trapped gas reduced digestion efficiency and increased cover stress.

How can CFD help prevent this?

CFD provides a 3D visualization of internal flow, revealing dead zones, circulation loops, and gas hold-up before equipment is installed.

Which mixing system works best in high-solids sludge?

Center-mounted axial-flow impellers are generally more effective in high-viscosity sludge, providing consistent motion and fewer stagnant zones.

Does cover design really affect process safety?

Yes — short skirt heights or weak guide columns can lead to unbalanced gas pressures and long-term mechanical deformation.

Further Reading

Explore resources and technical references related to anaerobic digestion and biogas optimization:

- Anaerobic Digesters: What They Are & What They Do

- EPA AgSTAR Program – How Does Anaerobic Digestion Work?

- U.S. Department of Energy – Enhanced Anaerobic Digestion Research

- Water Environment Federation – Anaerobic Digestion Fundamentals (Fact Sheet, PDF)

- Bioenergy Insight Magazine – Industry Trends & Case Studies

About LEC Partners

LEC Partners is a Cambridge, Massachusetts–based consulting firm advancing the bioeconomy through practical, data-driven solutions.

Our team bridges science, engineering, and investment to help clients develop, fund, and optimize sustainable technologies in anaerobic digestion, biogas, biofuels, carbon capture, and renewable chemicals.

From digester evaluations to process design and techno-economic analysis, LEC delivers independent insight and hands-on expertise that improve performance, reduce risk, and move clean technologies from concept to commercial success.

Meet the Project Team

John Forcier, P.E. — Anaerobic Digestion and Wastewater Systems

John is a civil and environmental engineer with over 50 years of experience in anaerobic digestion, biogas systems, and renewable energy integration. A recognized leader in agricultural and municipal digester design, he has supported more than 75 biogas installations across North America, specializing in co-digestion, RNG upgrading, and wastewater treatment applications.

Greg Benz, P.E. — Bioreactor Mixing and Process Engineering

Greg is a veteran process engineer with over 40 years of experience in bioreactor, agitation, and mixing system design for fermentation, wastewater, and biofuels applications. He has supported major anaerobic digester and bioprocess optimization projects worldwide, bringing a practical, data-driven approach to complex hydrodynamics and scale-up challenges.

Terry Mazanec, Ph.D. — Catalysis and Conversion Pathways

Terry is a seasoned R&D and technology leader with 40 years in thermochemical and catalytic conversion across RNG, biofuels, and hydrogen sectors. His work includes pioneering efforts in syngas cleanup, gas reforming, and biogas-to-chemicals pathways, making him well-suited for evaluating digester gas upgrading and integration strategies at wastewater treatment plants.

Ready to Improve Your Digester Performance?

If you’re facing mixing inefficiencies, foaming, or low gas yield, LEC Partners can help identify the root cause and engineer a practical solution.

Contact us to discuss your anaerobic digester performance and learn how CFD, rheology testing, and process redesign can optimize your results.

Have some questions?

Not sure where to start?

Let's start a conversation. We're here to help you navigate

the bioeconomy with confidence.