AI is Accelerating Materials Science Discovery and Synthesis Exponentially

by Kent Goeking, Managing Director

Introduction

One of the key barriers to the economic and technical success of many advanced energy technologies is the sub-optimum performance of critical inorganic materials used as catalysts, electrodes, dielectrics, and photovoltaics. Oxide materials in particular, such as metal oxides, perovskites, piezoelectrics, and ferroelectrics, offer significant promise of higher performance in these applications, but require critical breakthroughs to overcome current inefficiencies.

Traditionally, materials science research approaches are slow, labor intensive, and based on intuitive trial-and-error. However, in November 2023, Lawrence Berkley National Lab (LBNL) announced they had successfully combined the power of machine learning from the Google DeepMind GNoME model (trained on vast materials datasets) with a natural language processing model that can generate proposed synthesis recipes [1]. This combination allows for a tenfold increase in predicted stable compounds, and when combined with robotics, allows for high throughput synthesis and screening that will accelerate new materials development. LBNL calls their facility the Autonomous Laboratory or “A-Lab” for short.

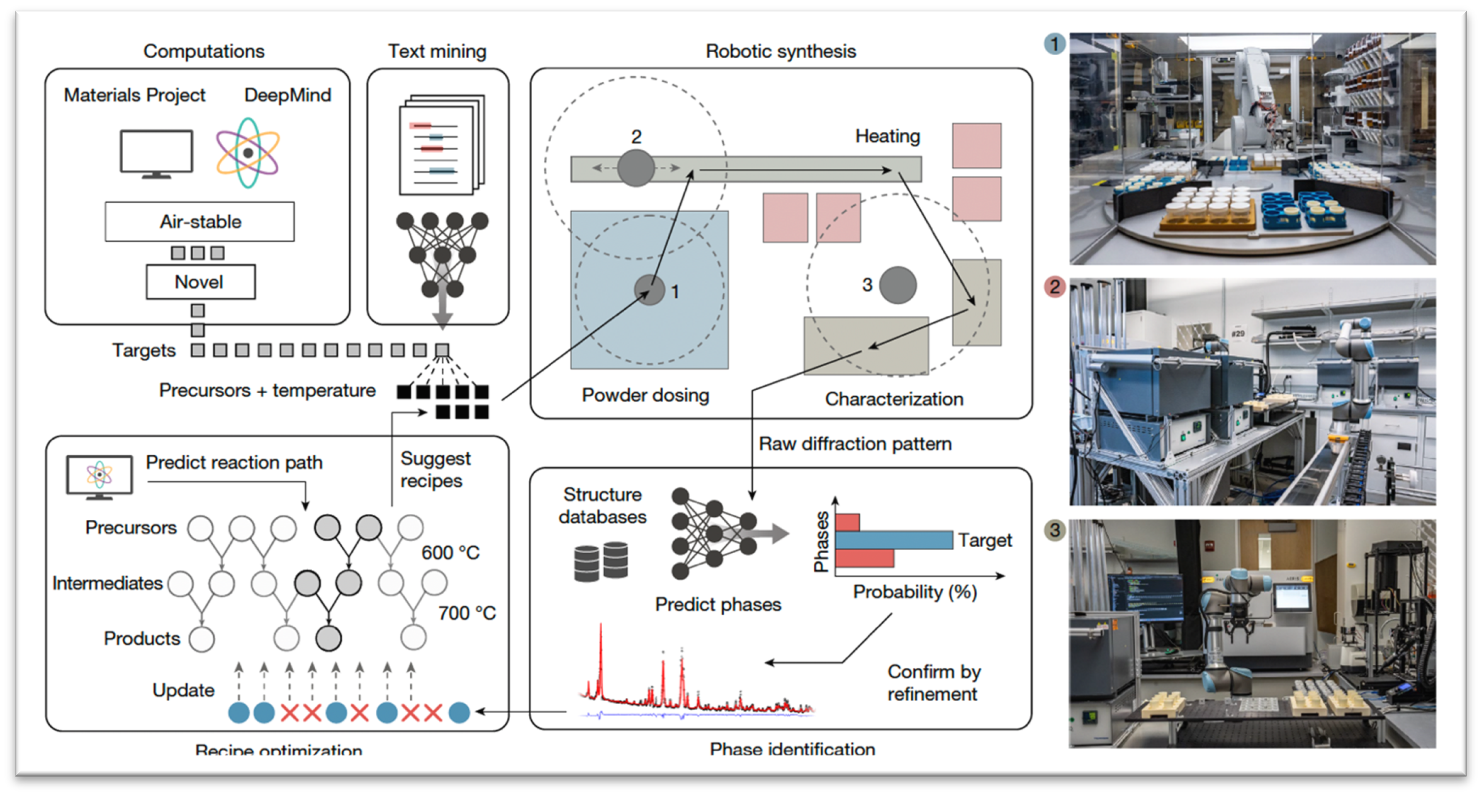

The A-Lab process starts with the selection of useful target materials predicted to be air-stable, then synthesis recipes are developed using ML models. These recipes are then experimentally tested using a robotic laboratory that automates the (1) powder dosing, (2) sample heating, and (3) product XRD characterization [1].

Example of Energy Materials Breakthroughs Needed

Here are a few examples of the breakthroughs needed:

- Solar conversion efficiencies can be improved with new materials, including perovskite semiconductors, metal oxides, and ferroelectrics. These materials need further functional improvements, such as increasing the photovoltaic efficiency, stability under solar irradiation, and compatibility with flexible substrates for broader application. Additionally, there is an opportunity to develop new materials with a broader range of light absorption.

- Energy Storage is one of the most effective areas for materials to achieve significant performance improvements. For example, finding new electrode materials for lithium-ion/sodium-ion batteries will improve energy density and charge-discharge rates. New materials that demonstrate the ability to endure high cycling rates with stability, reduced charge times, and use environmentally benign materials. Supercapacitors can also benefit from improvements in dielectric materials and electrodes to increase energy density while maintaining high power density, improving cycle stability, and reducing costs.

- Hydrogen technology requires the addition of functional materials, particularly metal oxides, for improved electrodes and catalysts for the electrochemical production systems, as well as electrodes and catalysts in fuel cells. Materials challenges include improving the efficiency and durability of the catalysts, reducing the operating temperature of fuel cells, and finding cost-effective alternatives to rare or expensive materials.

- Energy harvesting, the process of capturing and converting energy from the surrounding environment into electrical energy, is enabled by piezoelectric and ferroelectric materials. These materials generate electricity when mechanically stressed (vibrations, pressure, movement). There is a need to enhance the electrical output of these materials, improve their mechanical properties for better durability, and develop materials that can work efficiently across a wide range of frequencies and motion types.

Google DeepMind discovers 10x more stable compounds

Work has been ongoing for decades to catalog all known inorganic compounds, their crystal structures, and predicted properties. Two of the most prominent efforts are the Inorganic Crystal Structure Database (ICSD), run by the Institute for Information Infrastructure (Germany), and the Materials Project (MP) run by LBNL. The ICSD contains over 281,000 known inorganic crystal structures, with 12,000 new structures added annually. The Materials Project provides complementary computed information on known and predicted materials, as well as powerful analysis tools to inspire and design novel materials, including quantum mechanical calculations, and information on their basic electronic structures and thermodynamics.

By combining these two databases and others, Google DeepMind recently reported they have expanded the number of crystal structures predicted to be thermodynamically stable from 281,000 to over 2.2 million, nearly an order of magnitude enhancement in the potential materials available [2]. For example, the DeepMind ‘s model (GNoME) has been applied to layered materials promising for electronics and energy storage. Currently, there are approximately 1,000 layered materials known to be stable. GNoME has increased this number to 52,000. Similarly, the GNoME models found 528 new promising Li-ion conductors for battery technology. GNoME has also predicted 15 candidates promising replacements for LiCoO2 in rechargeable batteries. Now the job of materials scientists is to synthesize and experimentally characterize this explosion of new materials possibilities.

LBNL’s A-Lab

The keystone piece of this effort has now been demonstrated by LBNL through their A-Lab facility. They combined with the data resources described above with a natural language processing model, trained on the body of materials science literature, to autonomously plan the synthesis approach (component powder ratios, temperature, time). The A-Lab then robotically executes the mixing and sintering synthesis recipes and interprets the results of experiments with automated XRD scans. This combination of AI and robotics significantly accelerates the rate of new compound realization.

In LBNL’s paper, they describe their proof-of-concept trial, where 58 air-stable target compounds were selected using the Materials Project output and the A-Lab, then generated the synthesis recipes, executed those recipes, and then characterized the samples produced. When the predicted recipe did not produce the desired compound, active learning was used to close the loop by proposing improved follow-up recipes. During the 17 days of the trial, the A-Lab successfully synthesized 41 of the 58 target materials over a wide range of 33 elements and 41 structures. Many of the remaining 17 will also be synthesized after minor tweaks to the ML model. The A-Lab successfully realized new materials at the rate of >2 per day.

This approach mirrors a similar innovation in Synthetic Biology, where centralized automated labs have been designed, called Bio-Foundries, to automate and accelerate the pace of synthetic biology organism improvement. When applied to materials science, the automated laboratory allows for high throughput experimental realization of promising new materials identified using advanced materials property prediction models. Automation is certainly key to discovery. The major advance is to allow machine learning models to autonomously interpret data and make decisions based on that data. This mimics the human “intuition” that often guides researchers in their synthesis efforts, and is based on an accumulated background knowledge that informs our decision-making.

Conclusion

Although the focus was primarily on inorganic oxide materials in the above studies, there is no reason why this approach cannot be applied to other fields, such as metallurgy, polymer production, or other materials classes. We are entering a new era of Materials Science acceleration, hang on.

About the Author

Dr. Ken Goeking is a Managing Director at LEC Partners. He has over 30 years of experience in developing and deploying next-generation business and technology solutions. He has a Ph.D. in Materials Science and Engineering, and also led the management consulting practice of Accenture management consulting firm in Thailand. Kent lives in Thailand and has assisted several major companies in SE Asia in developing advanced biotech capabilities as they migrate to biobased products from their historical petrochemical and agricultural commodity markets. He assists LEC clients in matters involving pyrolysis, biochar, precision fermentation, Synthetic Biology, health and wellness bioproducts, and oversees LEC operations in SE Asia and India.

About LEC Partners

LEC Partners has over 180 experts that can help navigate your bioeconomy needs. If you need assistance with your bioenergy project(s), please contact us.

References

- Szymanski, N.J., Rendy, B., Fei, Y. et al.An autonomous laboratory for the accelerated synthesis of novel materials. Nature 624, 86–91 (2023). https://doi.org/10.1038/s41586-023-06734-w

- Merchant, A., Batzner, S., Schoenholz, S.S. et al.Scaling deep learning for materials discovery. Nature 624, 80–85 (2023). https://doi.org/10.1038/s41586-023-06735-9

Have some questions?

Not sure where to start?

Let's start a conversation. We're here to help you navigate

the bioeconomy with confidence.